Sustainability Report

"Healthy rest improves the quality of life”

Our Mission has always been to constantly improve, day after day, the quality of sleep and the level of comfort and ergonomics offered by each of our products; a commitment that cannot ignore a broader vision, attentive to the well-being of the planet just as we have always been attentive to the well-being of people.

The first Sustainability Report of B&T SpA , owner of the Dorelan brand, was born with this awareness: an important starting point for telling ourselves, reporting the results obtained but above all for planning future commitments and challenges. A transparency tool that we think can accompany us towards sustainable growth, strong in the roots and founding values of our company.

Our concept of sustainability

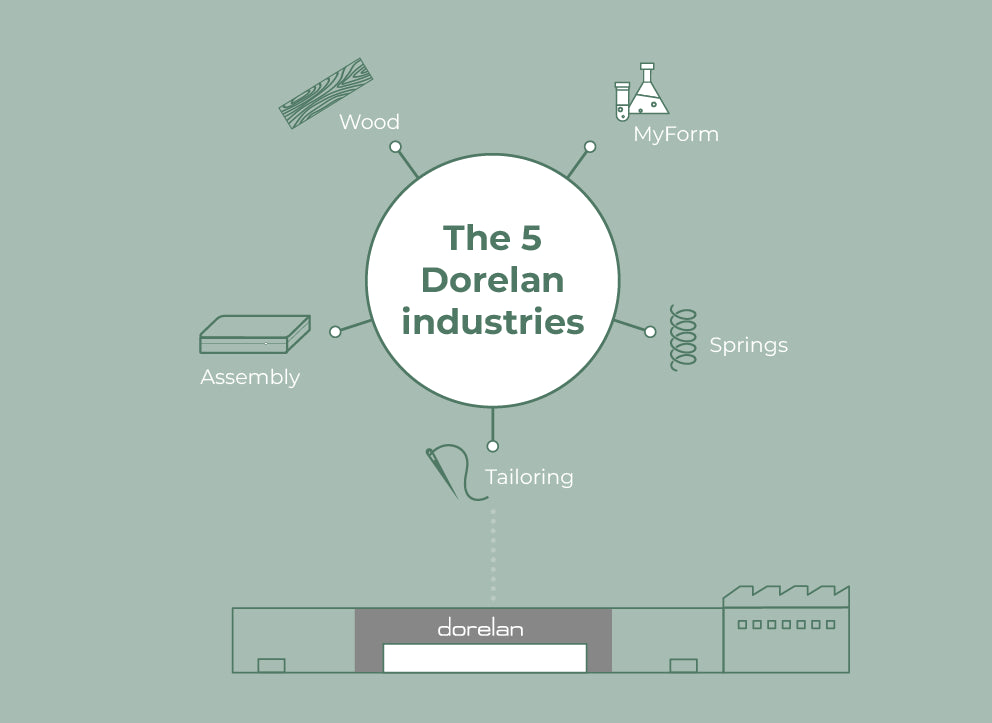

The great competitive advantage comes from the presence of five companies in one, aimed respectively at the wood, MyForm®, metalworking, tailoring and assembly sectors. This characteristic renders us unique and is a decisive factor in the creation of the product and its promise: well-being.

Each department deals with a specific area by vertically developing technological innovations dedicated to every component, obtaining patents that allow us to create durable and aesthetically excellent bed bases, spring systems of absolute reference on the international scene.

This choice also allows us to significantly reduce the environmental and economic impacts of our supply chain. To this end, we process all materials in-house, reducing incoming transport and almost completely eliminating the primary packaging that accompanies semi-finished products. This translates to a significant reduction in both the amount of waste we generate and the number of vehicles needed for transport from suppliers to our plants and the associated emissions.

2000

Articles produced every day

100%

Energy used from renewable sources or green certificates

96%

Waste sent for recovery

Our people

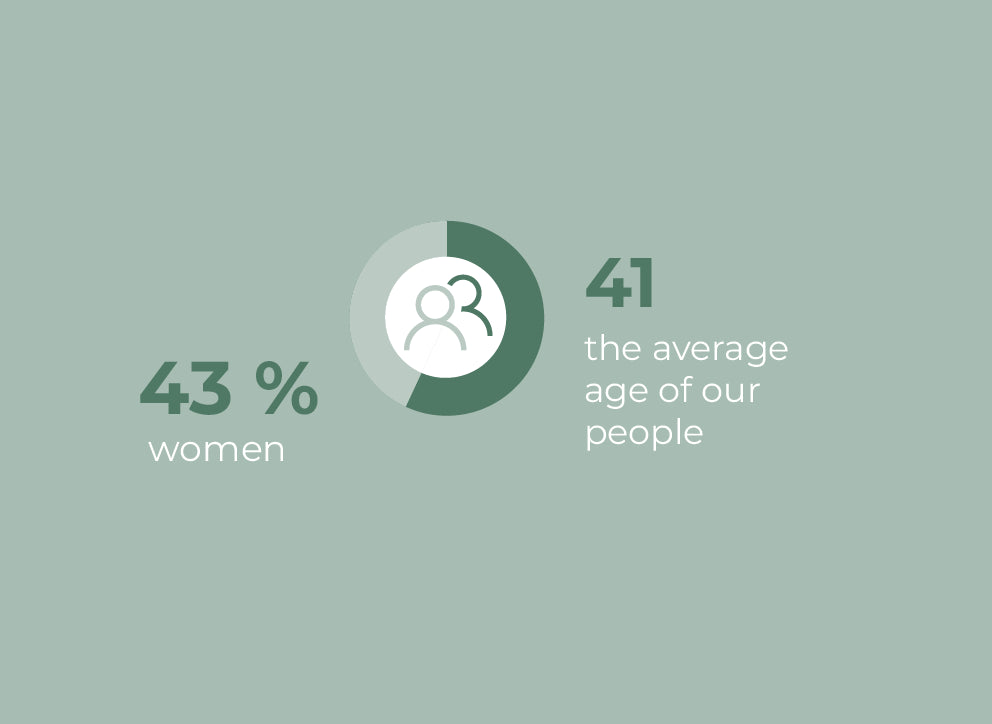

Since our inception, we have strongly believed that the core of our success is the people who work for and with us. Over the years, we have made a concrete commitment to providing a peaceful, healthy and safety-conscious workplace (with the ISO 45001:2018 certification being proof of this). We have invested in training to ensure professional and personal development. What’s more, we ensure a fulfilling and stimulating work environment by sharing our goals and future vision with our employees. And we try to attract new talent without forgetting to gratify and enhance our current employees.

Health and safety of our customers

One issue of absolute importance to us at Dorelan, regarding which we have no doubts: ourcustomers must always be totally satisfied with the quality and safety of our products. For us, that has always been non-negotiable. This is precisely why we have long been investing in national and international certification processes.Our certifications are recognitions of reliability and credibility. They attest to the application and maintenance of a management and work organisation system that complies with the relevant standards and their evolution over time.

Circular Economy

Our raw materials are all of Italian origin purchased from certified and qualified producers . The environmental impact of the individual raw materials entering the production processes is rather limited and does not in itself represent a relevant material issue; furthermore, our choice to process all components internally allows us to significantly reduce the emissions linked to the transport of these materials. The true impact of our raw materials is recorded when the product reaches the end of its life; developing solutions and materials with the lowest possible impact at the end of life.